OnStar for Your Gas Detection Program

How are organizations leveraging historical and real-time data to keep workers safe? As with auto safety systems and services, one type of data isn't enough for your gas detection program.

- By Kimberly Madia

- Jun 01, 2017

To keep drivers and passengers safe, General Motors, Ford, Volkswagen, Honda, and other major auto manufacturers are offering new safety systems and services. Safety innovations in the auto industry are garnering media attention, as well as vast investment dollars. For example, at the 2017 Consumer Electronics Show in Las Vegas, Vehicle Safety Systems captivated audiences—with 12 companies winning Innovation Awards in the Vehicle Intelligence category.

One vendor, CoDriver by Jungo Connectivity, uses learning algorithms to provide camera-based analysis of the driver's state of mind for advanced safety and autonomous car scenarios. Also, Ford is now offering Amazon Alexa in vehicles to add to the onboard safety system, which offers Automatic Crash Response and Emergency Services, Vehicle Diagnostics, and much more.

The backbone of these services is safety data, and safety data is made up of two types: Historical Data and Real-Time Data. Historical data is collected over time and used to understand conditions and trends. Historical data can be useful in helping to predict the likelihood of certain outcomes and predictive analyses. In auto safety, historical data is used to determine the optimal time to change brakes, tires, or oil.

Real-time data is delivered to end users immediately after it is generated. In auto safety for example, this could be turn-by-turn driving directions, EMS dispatch with the touch of a button, or an Amber Alert response with a voice command. Real-time data is needed and valued in the moment. Learning that you were supposed to take a left turn two hours after passing the exit isn't helpful. Similarly, dispatching EMS services to assist in an accident, even minutes after it happens, puts people at risk. Real-time data must be acted on in the moment before the opportunity is lost forever.

The reality is we need both types of data to stay safe. We shouldn't have to choose between knowing in real-time about poor weather conditions and getting engine diagnostics to ensure optimal oil changes.

Real-time and historical data are also used in many other consumer applications such as home safety systems and wearable fitness devices. But what about gas detection programs? How are organizations leveraging historical and real-time data to keep workers safe? As with auto safety systems and services, one type of data isn't enough for your gas detection program.

Most organizations have at least started to use historical data as part of their gas detection programs. For example, reports and documentation that demonstrate compliance with bump or calibration requirements are common. Historical data is required to assess your gas detection program across hazards, equipment, and people over time.

- Hazard Management—Organizations need a detailed history showing all gas alarms, when they happened, and where they occurred. Knowing which hazards exist helps build the right safety program including PPE, training policies, and work procedures. Safety leaders can study alarm trends and build graphs to make sure exposures are decreasing over time.

- Gas Detector Management—Often required by regulatory bodies or corporate mandates, reports about equipment health confirm gas detectors are compliant for field use. Safety leaders should be able to easily produce instrument history and records, such as sensor history and battery life, that confirm equipment health. Equipment settings and firmware should also be documented.

- People Management—Safety leaders need to keep track of who used which instruments, when, and where. User history demonstrates that all workers had the proper gas detectors.

Real-time data for gas detection is emerging as a top requirement for gas detection programs. Challenges getting data in real time are being solved with the ubiquity of Wi-Fi, cell, and satellite networks. But it is very difficult to understand what data is needed in real time. Real-time data from safety systems is voluminous—vehicle data, lone worker data, gas data, GIS data, and biometric data are just a few sources. All of these could potentially be relevant in a gas detection program. However, in an emergency situation, a supervisor doesn't want to be inundated with real-time alerts, just the data that is actionable and meaningful in the moment.

Talking with customers across continents in industries spanning oil and gas, wastewater treatment, and manufacturing, three real-time data points emerged as essential:

- Gas detection data. Gas detection should be the basis to build real-time data initiatives. Knowing gas levels is required in the moment and will dictate the emergency response protocol.

- Panic alerts. Workers need to press a button and be assured EMS services are responding immediately.

- Man down alerts. If a person is unable to move or succumbs to a hazardous gas, automated alerts should dispatch emergency response services.

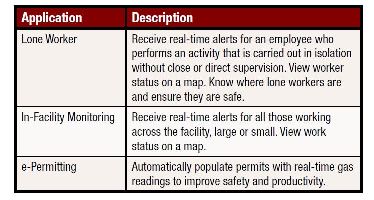

Some applications of real-time data are explained in the chart below.

As you evaluate vendors offering real-time data as part of their gas detection programs, here are some key design principles to consider:

- Pick gas detection vendors that use all available connectivity channels including Wi-Fi, cell, and satellite. Some gas detection solutions are partnering with specific cell providers, which means customers must invest in both gas detection programs and a specific data provider.

- Focus on simplicity of design. Some gas detection vendors are providing real-time data apps, which require workers to take actions such as pushing a button every few hours to check in. Instead, look for vendors that allow workers to focus on their jobs without needing to use a safety app. If they are already carrying a gas detector, why burden them with other devices that may be redundant? Let the gas detector do its job, leverage the gas detector fully to maximize your investment, and any apps should enhance the instrument, not shift attention from the gas detector.

- Pick a gas detection vendor with built in man down and panic alarms because these are the most essential real-time alerts. Picking multiple vendors could mean multiple devices and multiple apps.

- Look for a gas detection vendor that supports communication across the gas detection fleet, spanning personal and area monitors. You need a single software solution to provide real-time alerts on all types of gas detectors.

- Look for gas detection vendors that offer real-time alerts to supervisors that will also display alerts on instruments in close range. When working in a small team, it is helpful to see all readings from all workers on the instruments and also ensure those readings are sent to the supervisor in real time.

- Look for solutions that give you flexibility to detect hazardous gases depending on your situation. A good rule of thumb is to look for instruments that detect five gases.

- Look for vendors who open up data to customers, and make sure data is available via an API.

With real-time data at their fingertips, safety leaders can view a map of workers at any time during the work day and see their statuses. Real-time data eliminates the need for check-ins, automatic or otherwise, because supervisors can easily view a map and understand both worker and instrument status.

As investment increases in consumer electronics for safety, let's also consider innovation in gas detection programs. Don't pick between historical data and real-time data—find a gas detection program that uses both types of data. Don't choose between analyzing trends and dispatching emergency services at the right time, because you need both to stay safe in the moment.

This article originally appeared in the June 2017 issue of Occupational Health & Safety.